China PE Gas Pipe Supplier

The construction and installation of PE gas pipes require attention to the following: when laid underground, the thickness of the soil covering the pipe top should be ≥0.6 meters under sidewalks and ≥0.9 meters under roadways, while maintaining a safe distance from other underground pipelines. For connections, hot-melt or electro-fusion methods should be used. Hot-melt connection requires controlling the temperature (210±10℃), pressure, and cooling time, while electro-fusion connection needs special welding machines and parameter setting according to pipe specifications to ensure firm and sealed joints. After installation, a strength test (with pressure 1.5 times the working pressure) and a tightness test should be carried out. Soapy water should be used to check the airtightness of the joints, and backfilling can only be done after confirming no leakage to ensure the safe operation of the pipeline.

Summary of Core Characteristics and Advantages

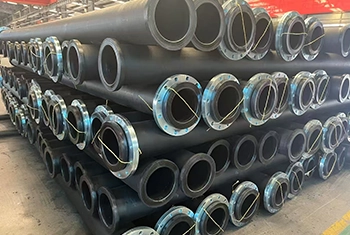

YAHONG

PE Gas Pipe

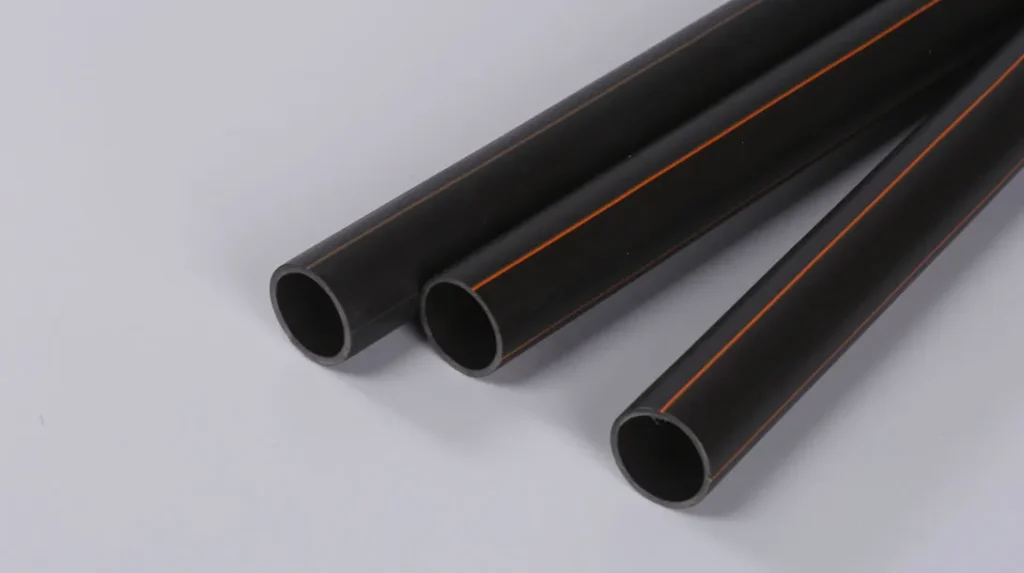

PE Threading Pipes

- Low-Temperature Environment (-50°C ~ 0°C)

- Ambient Temperature Environment (0°C ~ 40°C)

- Moderate to High-Temperature Environment (40°C ~ 60°C)

- Extreme High-Temperature Environment (>60°C)

1. Mechanical Property Changes

- Increased Rigidity, Reduced Flexibility: Low temperatures restrict the movement of PE molecular chains, causing the material to harden and become more brittle. For example, when the temperature drops below -20°C, the elongation at break of PE threading pipes may decrease from over 300% at room temperature to below 150%, making them prone to whitening or cracking when bent.

- Diminished Impact Resistance: Low temperatures reduce the material’s toughness, increasing the likelihood of cracks or fractures from external impacts (e.g., during construction). However, high-density PE (HDPE) exhibits slightly better low-temperature brittleness than low-density PE (LDPE) due to its tighter molecular chain arrangement.

2. Thermal Performance

- Volume Shrinkage: PE has a linear expansion coefficient of approximately (1.5–2.0)×10⁻⁴/°C. At low temperatures, the pipe may undergo minor deformation due to shrinkage, potentially affecting the tightness of joints (e.g., increased gaps in socket connections).

- Crystallinity Change: Low temperatures promote further crystallization of PE molecular chains. While this may reduce material transparency, it slightly enhances chemical corrosion resistance.

1. Stable Mechanical Properties

- Optimal Operating Range: This temperature range is ideal for PE threading pipes, balancing flexibility, rigidity, and impact resistance. For instance, at room temperature, PE threading pipes typically have a tensile strength of 10–20 MPa and an elongation at break exceeding 200%, facilitating construction bending and resistance to daily vibrations.

- Good Dimensional Stability: Thermal expansion and contraction are minimal, with negligible changes in pipe length and diameter, ensuring stable joint sealing for long-term buried or exposed use.

2. Chemical Performance Advantages

- Sustained Corrosion Resistance: PE’s stable molecular structure ensures it rarely reacts with acid, alkali, or salt solutions at room temperature, effectively protecting wires from chemical erosion.

1. Mechanical Property Degradation

- Onset of Softening: As the temperature approaches PE’s glass transition temperature (approximately 70°C), molecular chain segment movement intensifies, reducing material rigidity. For example, at 60°C, the tensile strength of PE threading pipes may decrease to 80–90% of their room-temperature value, making them prone to creep (slow deformation) under long-term heavy loads.

- Temporary Flexibility Increase: Short-term high temperatures slightly enhance material elasticity, aiding extreme-condition bending during construction. However, prolonged high temperatures accelerate performance degradation.

2. Thermal Deformation Risks

- Heat Resistance Limitations: The long-term temperature tolerance of PE threading pipes typically tops out at 60°C (some modified PE can withstand 70°C). Exceeding this may cause pipe expansion, deformation, or even damage to wire insulation (e.g., PVC insulation releasing hydrogen chloride gas at high temperatures).

1. Significant Performance Degradation

- Melting Risks: PE’s melting point ranges from 105–130°C (increasing with density), but noticeable softening occurs between 60–90°C. Pipes may collapse or stick together, losing their mechanical protection for wires.

- Chemical Structure Damage: High temperatures accelerate oxidative chain scission in PE, making the material brittle and cracked while releasing harmful substances (e.g., low-molecular olefins), posing environmental risks.

Yahong Products

Green Environmental Protection Building Materials

Product Accessories

YAHONG’s professional team will match the correct accessories for you according to the products and projects you need.