1. Basic Definition and Structure

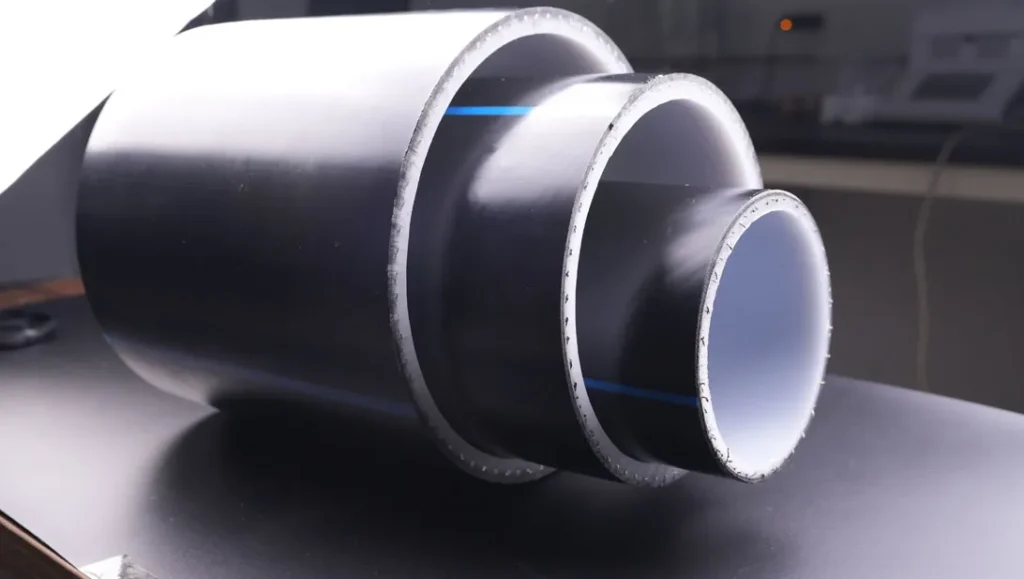

PE steel skeleton pipe is a composite pipe that uses high-strength steel wire (or steel strip) as the skeleton reinforcement material, with polyethylene (PE) plastic coated on both the outer and inner layers. Through special processes, the steel wire and plastic are tightly integrated to form a “rigid-flexible combined” composite structure.

- Core Advantage: It combines the high strength and rigidity of steel with the corrosion resistance, wear resistance, and flexibility of PE, solving the problems of easy corrosion in traditional metal pipes and insufficient strength in pure plastic pipes.

2. Main Performance Characteristics

| Performance Dimension | Specific Performance |

|---|---|

| Strength and Stiffness | The steel skeleton provides strong support, with excellent pressure resistance, suitable for high-pressure water and gas transmission scenarios. |

| Corrosion Resistance | PE material has strong chemical stability, resistant to acid, alkali, salt, and other media, with a service life of over 50 years. |

| Temperature Resistance | The long-term working temperature range is -20°C~60°C, and it can withstand short-term high temperatures of 70°C, superior to ordinary PE pipes. |

| Connection Convenience | It adopts electrothermal fusion connection or flange connection, with high joint strength, good sealing performance, and fast installation without complex tools. |

| Hygienic Safety | The material is non-toxic and pollution-free, meeting drinking water transmission standards, and can be used in tap water, food, and chemical industries. |

| Impact Resistance | Good flexibility, strong resistance to geological settlement and impact, adapting to complex terrains and harsh environments. |

3. Application Fields

PE steel skeleton pipes are widely used in the following scenarios:

- Municipal Engineering: Urban water supply pipelines, drainage and sewage pipelines, gas transmission pipelines.

- Industrial Fields: Chemical raw material transportation, industrial wastewater treatment, mine mortar transportation.

- Agricultural Irrigation: Farmland water conservancy projects, sprinkler and drip irrigation systems, water transmission pipeline networks.

- Construction Engineering: Building water supply, floor heating systems, fire pipelines, and indoor/outdoor drainage.

4. Production Process and Quality Standards

- Production Process:

- Steel wires (or steel strips) are welded or wound to form the skeleton layer;

- PE plastic is melted and coated on the inner and outer sides of the skeleton layer through an extruder to form a complete pipe;

- After cutting, inspection, and labeling, the finished product is stored in the warehouse.

- Quality Standards:

- Complies with national standards such as Steel-Plastic Composite Pressure Pipe (GB/T 18742.2);

- Must pass multiple performance tests, including pressure tests, ring stiffness tests, and corrosion resistance tests.

5. Comparative Advantages with Other Pipe Materials

| Pipe Type | PE Steel Skeleton Pipe | Pure PE Pipe | Steel Pipe |

|---|---|---|---|

| Strength | High (reinforced by steel skeleton) | Medium-low | High |

| Corrosion Resistance | Excellent (protected by PE coating) | Excellent | Poor (prone to rust) |

| Weight | Light (easy for transportation and installation) | Light | Heavy |

| Cost | Medium (lower than steel pipes, higher than pure PE pipes) | Low | High |

| Application Scenarios | High-pressure, corrosive environments, complex terrains | Low-pressure, ordinary environments | High-pressure, non-corrosive environments |

6. Installation and Maintenance Considerations

- Installation Key Points:

- Ensure interface cleanliness before pipe connection; strictly control heating time and temperature for electrothermal fusion connection;

- When laying underground, avoid sharp objects, and backfill soil should be compacted in layers to prevent uneven stress on the pipeline.

- Maintenance Suggestions:

- Regularly inspect the sealing performance of pipe joints to avoid leaks;

- When transporting high-temperature media, take heat insulation measures to prevent sudden temperature changes from affecting pipe performance.

7. Development Prospects

With the country’s emphasis on green building materials and infrastructure construction, PE steel skeleton pipes will usher in broader application spaces in fields such as municipal pipeline renovation and rural revitalization water conservancy projects during the “14th Five-Year Plan” period. In the future, its production process will further develop towards intelligence and efficiency, promoting industry technological upgrading.

For specific specifications, models, or engineering cases, please provide detailed requirements.