China PPR Pipe Supplier

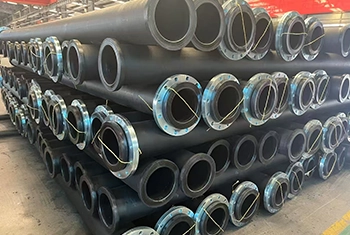

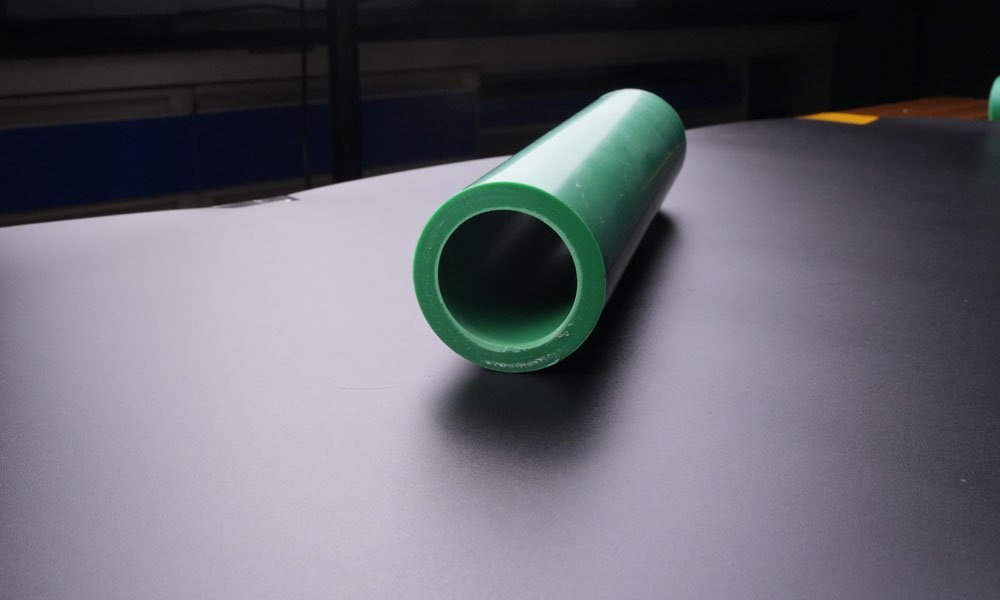

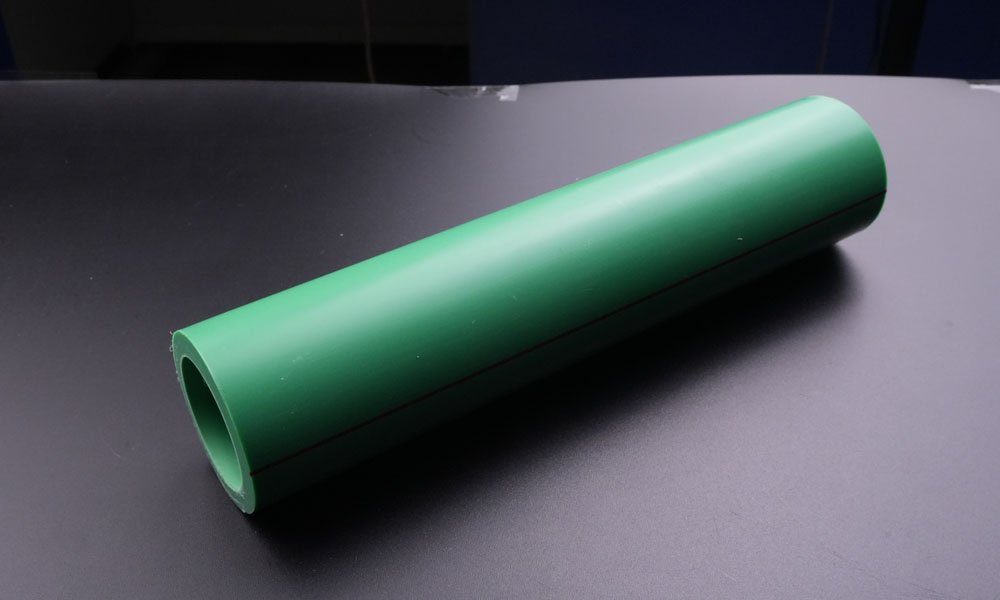

PPR pipe (random copolymer polypropylene pipe) is a thermoplastic plastic pipe formed by extrusion of random copolymer polypropylene. It has the core advantages of resistance to high temperature and high pressure (working temperature can reach 70°C, short-term temperature resistance of 95°C and pressure resistance is better than traditional PVC pipe), hygiene and environmental protection (non-toxic and odorless, meets drinking water standards, not easy to scale and breed bacteria), light and easy to install (density is only 1/7 of metal pipe, can be hot-melt connected and the interface has high strength and good sealing), and long service life (up to 50 years under normal conditions of use).

Core characteristics of PPR pipes

PPR pipes are widely used in many fields due to their excellent performance. In residential water supply systems, it safely transports hot and cold water and ensures the health of household water with its hygienic, environmentally friendly, heat-resistant and pressure-resistant characteristics; in commercial and industrial buildings, its advantages of being light, easy to install and having a long service life are highlighted. It can efficiently build centralized water supply and air-conditioning circulating water systems for hotels and hospitals, reducing construction and maintenance costs. In floor heating projects, the flexibility and low-temperature resistance of PPR pipes are adapted to the needs of floor heating coils to achieve uniform heating; when used for agricultural irrigation, its corrosion resistance is not afraid of acidic and alkaline environments, it can stably transport water sources, and its light weight makes it easy to lay in the field, greatly improving irrigation efficiency. Whether it is for civil or industrial scenarios, PPR pipes have become an ideal choice for pipeline projects with their reliable performance and high cost-effectiveness.

YAHONG

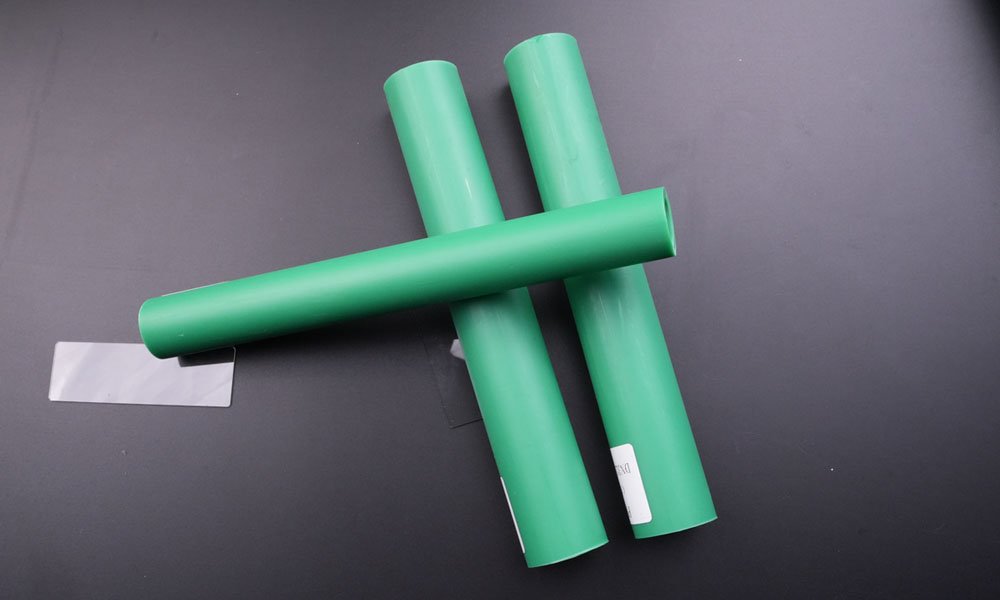

PPR Pipe

- Cold water pipes: have a lower pressure rating (such as PN1.0, PN1.6), and are marked in blue or without color.

- Hot water pipes: have a higher pressure rating (such as PN2.0, PN2.5), are usually red or with red lines, and antioxidants are added to the material to enhance heat resistance.

Application of PPR Pipe

- Building Water Supply and Drainage

- Heating and Geothermal Systems

- Industrial Pipeline Field

- Agriculture and Horticulture

- Cold and Hot Water Supply Systems

- Indoor Cold Water Pipes: Replaces traditional galvanized steel pipes to avoid water pollution caused by rust. It is lightweight (about 1/9 the weight of steel pipes) and requires no welding—hot-melt connection simplifies installation and reduces construction costs. For example, DN20-DN32 PPR pipes are commonly used in kitchen and bathroom cold water pipelines in households.

- Hot Water Pipes: Outstanding high-temperature resistance (long-term use at 70°C, short-term up to 95°C) makes it suitable for hot water transportation in solar water heaters, wall-hung boilers, etc. In hotel guest room hot water circulation systems, oxygen-barrier PPR pipes are often selected to prevent oxygen infiltration, which could accelerate corrosion of heating equipment.

- Drainage Systems

PPR pipes are used as drainage branch pipes in some scenarios, especially in corrosive environments (e.g., laboratory or chemical plant workshop drainage). However, their hardness is slightly lower than PVC pipes, so large-diameter main drainage pipes still rely on PVC.

- Underfloor Heating Coils

- S5 or S4 series PPR pipes (thicker walls for high pressure resistance) are laid under floors for indoor heating via hot water circulation. Their good flexibility allows bending into coils, and the moderate thermal expansion coefficient (0.15mm/m·°C) minimizes deformation when paired with expansion joints.

- Case: In central heating renovations for northern households, DN20 PPR pipes are often used as underfloor heating pipes, laid at 15-20cm intervals to maintain room temperatures around 20°C.

- Radiator Connection Pipes

Replaces metal pipes to prevent rust and leakage at joints, with easy installation. For example, DN25 PPR pipes connect steel radiators to main pipes; hot-melt connections ensure good sealing, with a service life of over 50 years (under specified temperature and pressure).

- Chemical Fluid Transportation

- Resistant to acids, alkalis, salts, and other chemical media, suitable for food processing (transporting juice, soy sauce), pharmaceutical factories (transporting liquid medicine), electroplating workshops (transporting electroplating solutions), etc. For instance, a food factory uses PPR pipes for citric acid solution transportation to avoid metal ion contamination, complying with food-grade hygiene standards (meeting GB/T 17219 health performance testing).

- Note: For high-temperature or strongly corrosive media, choose PPR pipes with higher pressure ratings (e.g., PN2.0MPa or above) and use flange connections for enhanced sealing.

- Compressed Air Pipes

In small factories or workshops, they replace traditional galvanized steel pipes to prevent rust from clogging pneumatic equipment. For example, DN15-DN50 PPR pipes are used in air supply pipelines for automated production line cylinders, operating stably under ≤1.0MPa pressure.

- Irrigation Systems

- In farmland drip irrigation and sprinkler systems, PPR pipes serve as main or branch pipes, costing less than PE pipes with secure, leak-free joints. For example, greenhouse drip irrigation systems use DN63-DN110 PPR pipes as main channels, with DN20-DN32 capillary pipes connected via hot-melt fittings for precise irrigation.

- Weather Resistance: Outdoor use requires adding UV stabilizers to prevent aging from prolonged sun exposure, extending service life to over 10 years.

- Aquaculture

Water circulation pipes in fish and shrimp ponds leverage PPR’s corrosion resistance to prevent water pollution from metal pipes. For example, DN50-DN100 PPR pipes connect aeration pumps to ponds, with fittings enabling water circulation.

Yahong Products

Green Environmental Protection Building Materials

Product Accessories

YAHONG’s professional team will match the correct accessories for you according to the products and projects you need.